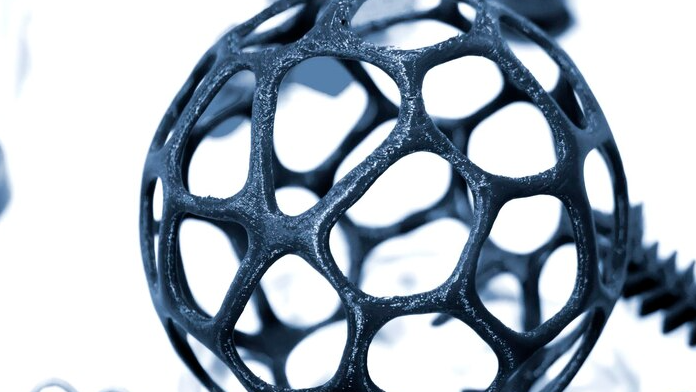

Enhancing your prints

Using supports, rafts, and other printing techniques to improve print quality.

When it comes to 3D printing, there are several techniques you can use to enhance the quality of your prints. Supports, rafts, and other printing techniques can help to improve print quality and ensure that your prints come out looking great.

- Supports: Supports are structures that are printed along with your model to provide additional support for overhanging parts. They are typically printed in the same material as your model, but can also be printed in a different material if necessary. Supports can be automatically generated by your slicing software, or you can add them manually to your model using CAD software. Removing supports after printing can sometimes leave marks on the surface of your model, but they are usually easy to clean up with some sandpaper or a file.

- Rafts: Rafts are thin layers of material that are printed underneath your model to provide additional adhesion and stability. They are especially useful for printing large or complex models, or models with small contact points. Rafts can be automatically generated by your slicing software, or you can add them manually using CAD software. Removing rafts after printing is usually easy, and they can help to prevent warping and other print issues.

- Brims: Brims are similar to rafts, but they are printed around the edges of your model rather than underneath it. They can help to prevent warping and provide additional adhesion, especially for models with small contact points. Brims are usually easy to remove after printing, and can be generated automatically by your slicing software.

- Layer Height: Changing the layer height of your prints can also help to improve print quality. A lower layer height will result in smoother surfaces and finer details, but will also increase print time. A higher layer height will result in faster prints, but with lower resolution and surface quality. Finding the right balance between print quality and speed is key to achieving great results.

- Bed Leveling: Ensuring that your print bed is level is critical for achieving good print quality. Uneven or warped beds can cause parts of your model to be under-extruded or over-extruded, resulting in poor quality prints. Most 3D printers have automatic bed leveling systems, but it’s always a good idea to manually check and adjust the bed level before each print.

- Cooling: Cooling is also important for achieving good print quality. A fan can be used to cool the filament as it’s being extruded, which can help to prevent stringing and other print issues. Many slicing software programs have settings for controlling fan speed during printing, which can be adjusted to achieve the best results for your specific model.

By using these techniques, you can significantly improve the quality of your 3D prints and achieve the results you’re looking for.