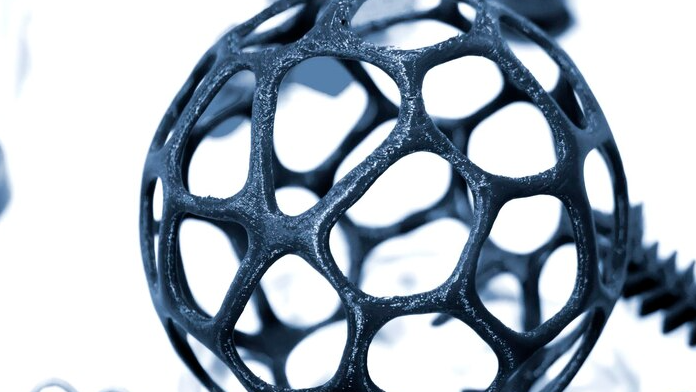

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), is a type of 3D printing technology that uses a liquid resin as the printing material.

With resin 3D printing, a digital model is sliced into thin layers, which are then projected onto the surface of a liquid resin using a light source. The light causes the resin to harden and solidify, layer by layer, until the entire object is formed.

Both SLA (Stereolithography) and DLP (Digital Light Processing) are 3D printing technologies that use photopolymer resin as the printing material. The main difference between the two lies in how the resin is cured to form the 3D object.

In SLA, a laser beam is used to selectively cure the resin layer by layer, based on the design. The cured resin hardens and adheres to the build platform, and the process repeats for each subsequent layer until the entire object is complete.

In DLP, a projector shines a UV image of each layer onto the resin, which is then cured all at once. This means that DLP printers can often print faster than SLA printers, but the surface finish may not be as smooth.

Overall, both SLA and DLP produce high-quality prints with fine details, but SLA may be better suited for complex geometries and intricate details due to its precision, while DLP may be faster and more cost-effective for larger prints.

Things to Consider for 3D Resin Printer Beginners

- Safety precautions: It is important to take appropriate safety measures when working with resin, such as wearing gloves and protective eyewear, ensuring proper ventilation, and disposing of resin waste properly.

- Post-processing: After printing with resin, the finished object may require additional post-processing steps such as cleaning, curing, and sanding to achieve the desired final result.

- Cost considerations: While resin printing can produce high-quality prints, it may also be more expensive than other forms of 3D printing due to the cost of resin materials and the need for specialized equipment.

- Environmental impact: Some resin materials may have a negative impact on the environment, and it is important to research and consider environmentally-friendly options.

- Maintenance: Like any piece of equipment, resin printers require regular maintenance and upkeep to ensure they continue to function properly and produce high-quality prints. This may include tasks such as cleaning the printer and replacing parts as needed.

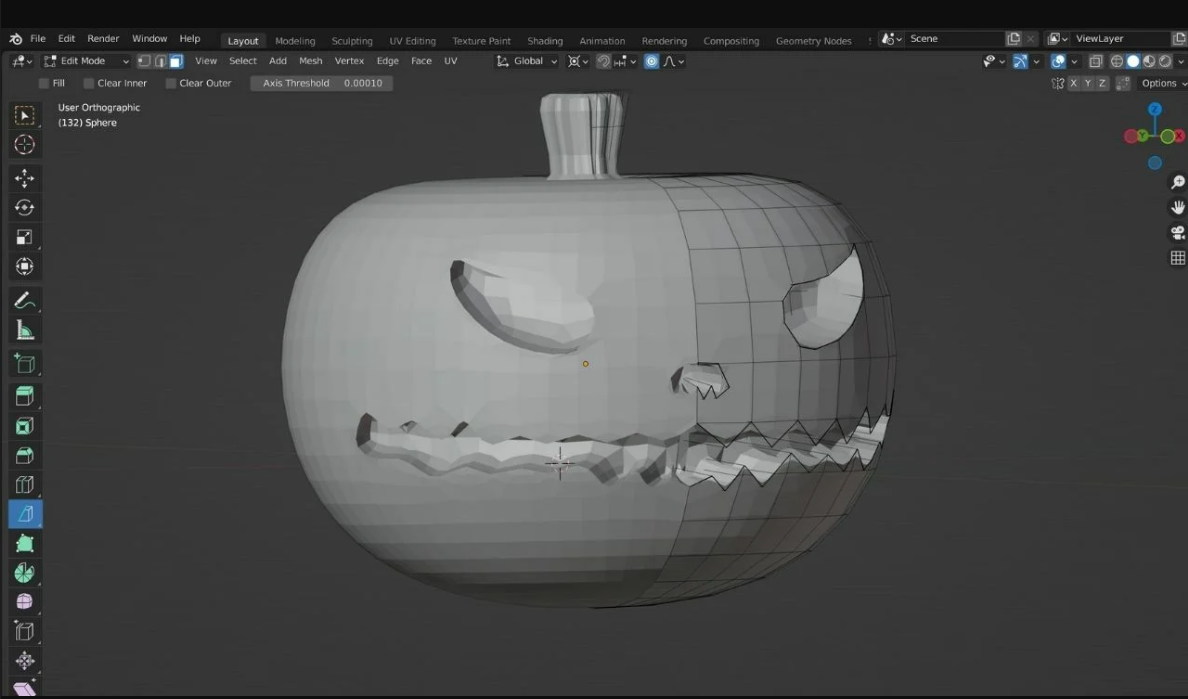

- Software and design considerations: In addition to learning how to use the printer itself, users will also need to become familiar with the software used to design and prepare 3D models for printing.

Cost of a Resin 3D Printer

The cost of a resin 3D printer can vary widely depending on factors such as the brand, size, and capabilities of the printer. Generally, resin printers tend to be more expensive than their FDM (filament-based) counterparts, but they are also capable of producing higher quality prints.

Entry-level resin 3D printers can cost anywhere from $200 to $500. These printers typically have a smaller build volume and may have more limited capabilities, such as lower resolution or slower printing speeds.

Mid-range resin 3D printers can cost anywhere from $500 to $2,000. These printers tend to have larger build volumes and more advanced features such as higher resolution, faster printing speeds, and more sophisticated software.

High-end resin 3D printers can cost upwards of $2,000 to $5,000 or more. These printers are typically used by professionals and businesses for applications such as rapid prototyping, jewelry making, and dentistry, and offer the highest levels of accuracy, speed, and versatility.

It’s important to keep in mind that the cost of a resin 3D printer is just one factor to consider when choosing a printer. Other factors such as the cost of materials, maintenance, and ongoing support should also be taken into account.

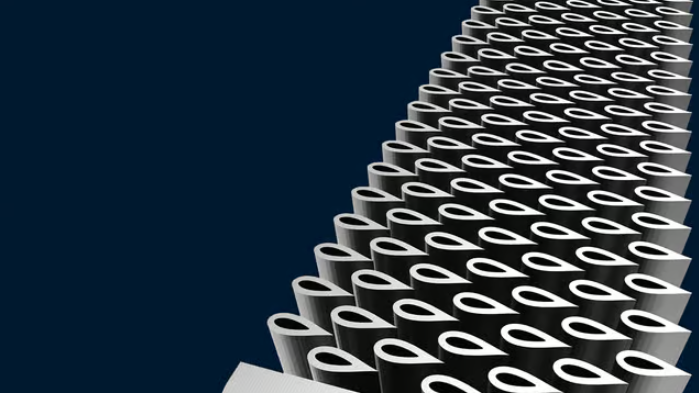

Resin 3D printing is capable of producing highly detailed, complex, and precise parts with a smooth surface finish. It is commonly used in applications such as jewelry making, dentistry, and prototyping. However, resin 3D printing can be more expensive and time-consuming than other types of 3D printing, and requires more careful handling and post-processing to ensure the final object is fully cured and safe to handle.

The Difference between Resin 3D Printing and Filament 3D Printing

Resin printing is typically done using a technology called stereolithography (SLA) or digital light processing (DLP), which use liquid resin that is cured by UV light to create solid objects. Resin 3D printing is capable of producing highly detailed, complex, and precise parts with a smooth surface finish. It is commonly used in applications such as jewelry making, dentistry, and prototyping. However, resin 3D printing can be more expensive and time-consuming than other types of 3D printing, and requires more careful handling and post-processing to ensure the final object is fully cured and safe to handle.

Filament printing is typically done using a technology called fused deposition modeling (FDM), which extrudes melted plastic filament layer by layer to create objects.

Setting Up a New Printer

The time it takes to set up a resin 3D printer can vary depending on the specific model and the level of experience of the user. However, most resin 3D printers come with clear instructions and are designed to be relatively easy to set up and get started with.

Steps involved:

- Unboxing: Remove the printer and all the components from the packaging.

- Leveling: Level the build platform to ensure the print bed is flat and level.

- Calibration: Calibrate the printer to ensure that it is properly aligned and the build plate is at the correct height.

- Resin filling: Fill the resin vat with the resin of your choice, taking care to avoid any bubbles or debris in the vat.

- Slicing: Use a slicing software to prepare your 3D model for printing, and transfer it to the printer’s SD card.

- Printing: Insert the SD card into the printer, select the desired file, and start the print.

The entire setup process can take anywhere from 30 minutes to several hours, depending on the specific printer and the level of experience of the user. However, once the printer is set up and calibrated, the printing process itself is usually quite straightforward and can be completed in a matter of hours, depending on the size and complexity of the print.

Pitfalls to Look Out For and to Avoid

Expectations:

- 3D printing can produce high-quality and detailed prints, but it requires some level of learning and experimentation.

- Resin printing may produce a strong odor and require careful handling to avoid any health risks.

- The post-processing of prints, such as cleaning and finishing, can be time-consuming and messy.

- While the technology has come a long way, failed prints and wasted material can still be an issue.

How to Avoid:

- Do your research and choose a reliable and well-reviewed printer to ensure a smoother printing experience.

- Take the time to learn about the different materials and settings to optimize your prints.

- Take necessary safety precautions when handling resin, such as wearing gloves and using a well-ventilated area.

- Follow proper cleaning and post-processing procedures to avoid any messy or time-consuming mistakes.

- Don’t be discouraged by failed prints. Troubleshooting and experimentation are part of the process, so stay patient and persistent.

Overall, 3D printing can be a rewarding hobby or profession, but it does require some learning, patience, and attention to detail. By being aware of potential pitfalls and taking the necessary precautions, you can enjoy the benefits of 3D printing and produce high-quality prints

Careers for 3D Resin Printing Experts

Having advanced resin 3D printing experience can open up various job opportunities in different industries. Here are some examples:

- Industrial design: You can work as an industrial designer, creating prototypes and mock-ups for new products using resin 3D printing technology.

- Manufacturing: You can work in manufacturing, using resin 3D printing to produce parts and components for a range of industries, including aerospace, medical, and automotive.

- Jewelry design: You can work as a jewelry designer, creating custom pieces using resin 3D printing technology to create intricate and detailed designs.

- Architecture: You can work in architecture, using resin 3D printing to create scale models of buildings and structures.

- Education: You can work in education, teaching students about resin 3D printing and how to use it to create complex designs and objects.

- Research and development: You can work in research and development, using resin 3D printing to create prototypes and test models for new products and technologies.

- Art and sculpture: You can work in the art and sculpture fields, using resin 3D printing to create unique and intricate pieces that would be difficult or impossible to create by hand.

Overall, the possibilities are vast and varied, and the field of resin 3D printing is still rapidly evolving, which means there are always new and exciting opportunities on the horizon.